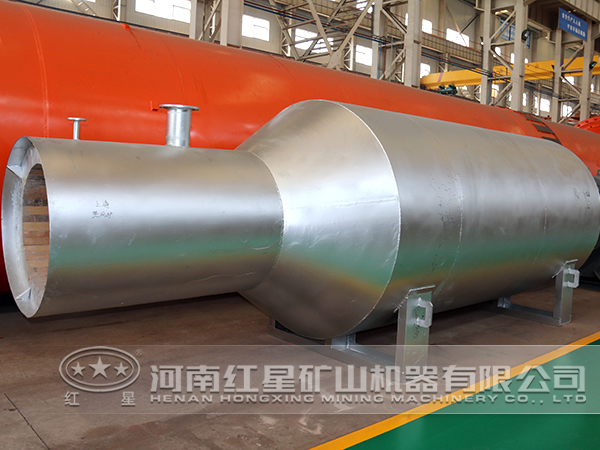

蒸汽烘干機,也稱為蒸汽式烘干機,蒸汽烘干機適用于榨油廠、浸出油廠,主要用于原料的軟化(兼烘干),提高原料的塑性,使扎胚機扎出的胚薄而不碎,達到后面工序要求,從而壓胚、蒸炒、壓榨、浸出 。

主要用于原料的軟化(兼烘干),提高原料的塑性,使扎胚機扎出的胚薄而不碎,達到后面工序要求,從而壓胚、蒸炒、壓榨、浸出 。

Steam dryer is mainly used by the oil-pressing plant and oil leaching plant to soften and dry materials and improves the plasticity of materials in order to make embryo formed by the plunging machine thin but unbreakable, and meet the later processing requirement like pressing, cooking, squeezing and leaching.

It is used to soften and dry materials and improves the plasticity of materials in order to make embryo formed by the plunging machine thin but unbreakable, and meet the later processing requirement like pressing, cooking, squeezing and leaching.

熱風爐

1、高節能低消耗:與立式軟化鍋相比,蒸汽式烘干機的電耗是立式的1/4-1/3,氣耗是立式的1/2-2/3。與目前臥式軟化鍋相比節氣10%-15%,長度短20%-30%,一年節省大量的潤滑油及維護保養費。

2、軟化 好:蒸汽烘干機采用臥式滾筒結構,能耗低、動力小、物料機內翻動均勻、克服了死角、軟化 好

3、工藝調整便利:蒸汽式烘干機選用無級調速 ,可根據物料入機水分不同,工藝參數不同,有效、方便地進行調節。

4、傳動方式特別:動力傳輸采用特別的軟傳動或齒輪傳動,設備磨順小,噪音低。

5、冰凝水排除安全:蒸汽烘干機特別的冷凝水排除設置,使設備在使用過程中,能有效的排除冷凝水,大幅度提高了蒸汽的加熱 。

蒸汽烘干機根據熱交換的原理,利用蒸汽散熱器散發的熱量,通過抽風風機不斷的吸風而產生的一個熱循環過程,使轉筒內的物料在旋轉的轉達筒內不斷正反翻動,而逐漸烘干。

The steam dryer based on the heat exchange theory uses the heat from the steam radiator to realize heat recycling through the continuous air draft by the exhaust fan. Materials in the drum of the dryer are turned over and over in the rotary drum, thus completing the drying process.

河南紅星礦山機器有限公司位于河南省鄭州市。是一家大型蒸汽烘干機廠家,生產的蒸汽烘干機具有布局合理、安裝方便等優點。蒸汽烘干機價格合理,歡迎新老客戶來廠參觀選購。

蒸汽烘干機廠家地址:中國-河南-鄭州-高新 產業開發區-檀香路-8號。